Release V2

In the UK, half a million shopping trolleys are abandoned annually. Costing British businesses £35m, Release fixes that.

Release the Electronic Trolley Lock for supermarkets

Overview

- In the UK, over half a million shopping trolleys are abandoned annually.

- It costs British businesses £35m a year, and that doesnt include environmental damages!

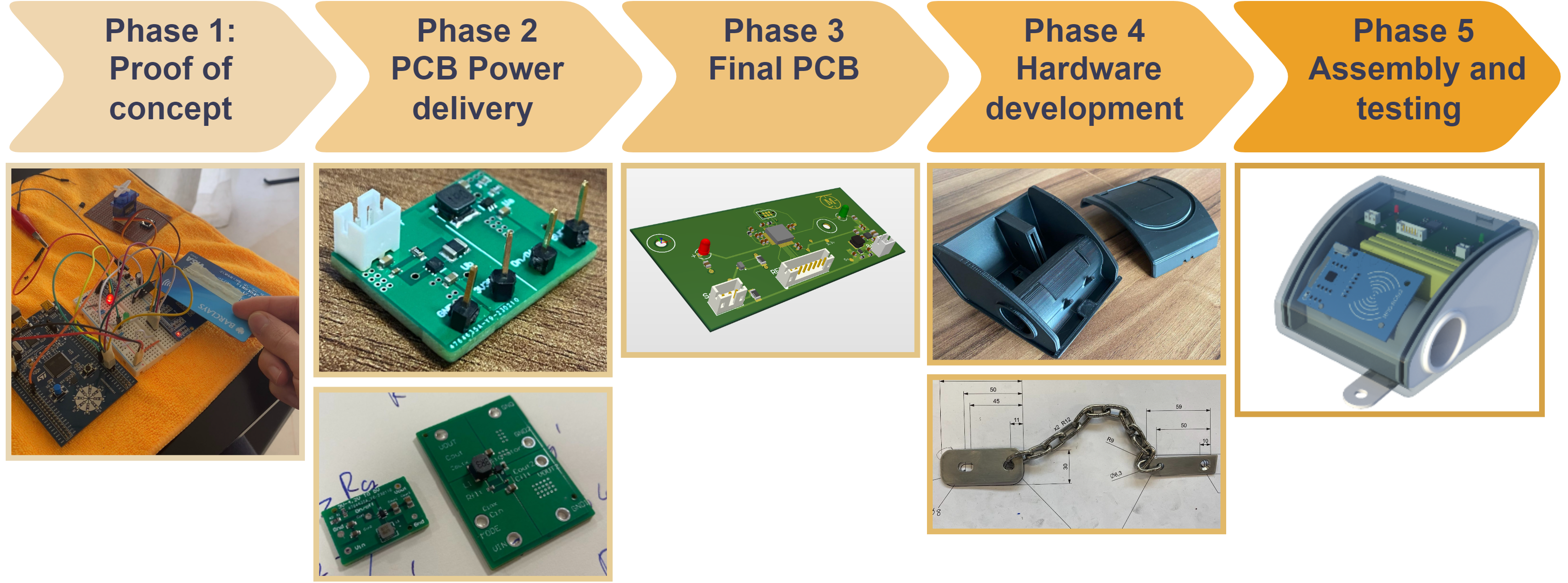

- Here is the engineering development to get to the finished prototype.

Methodology

Altium PCB Design

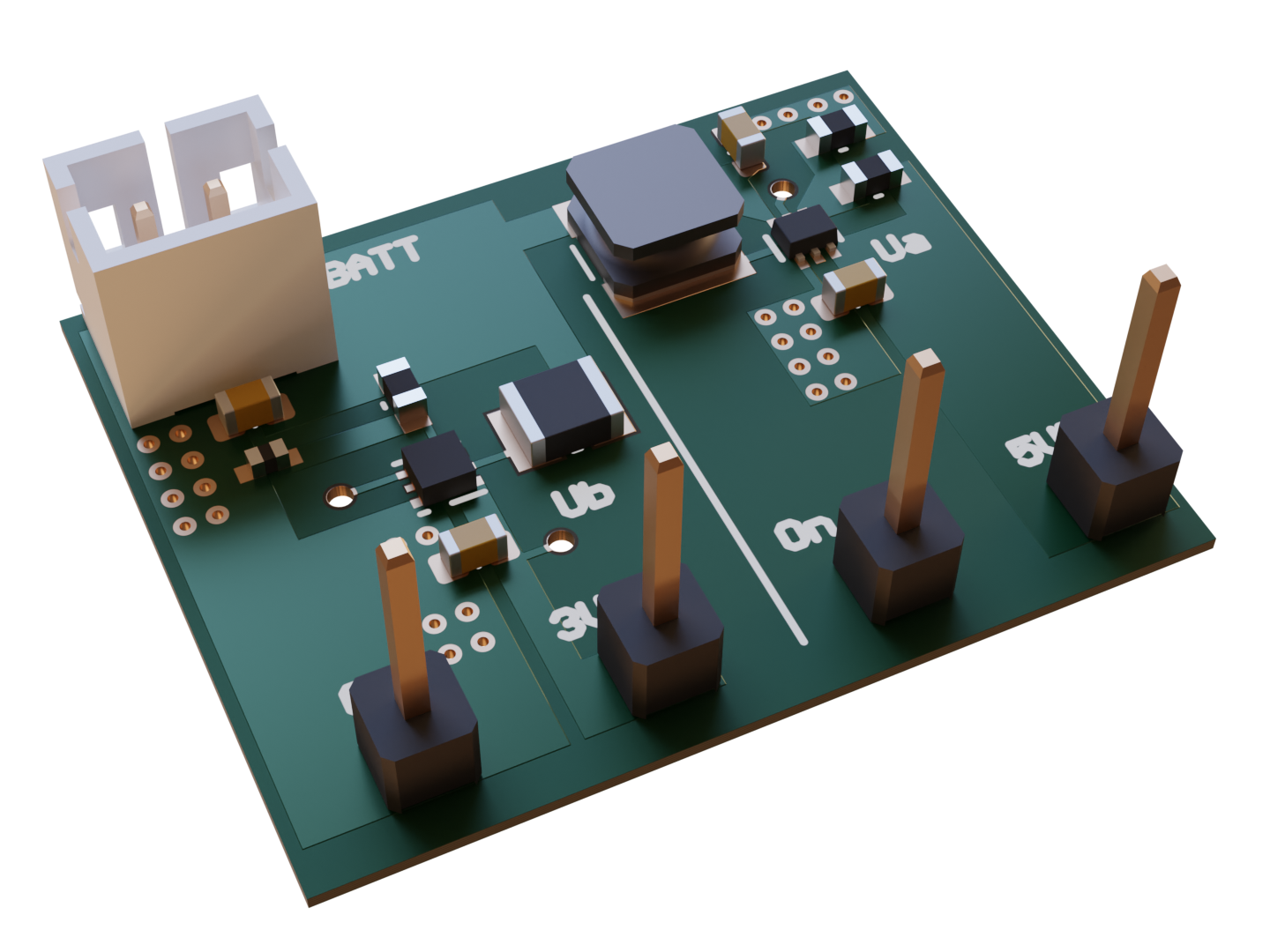

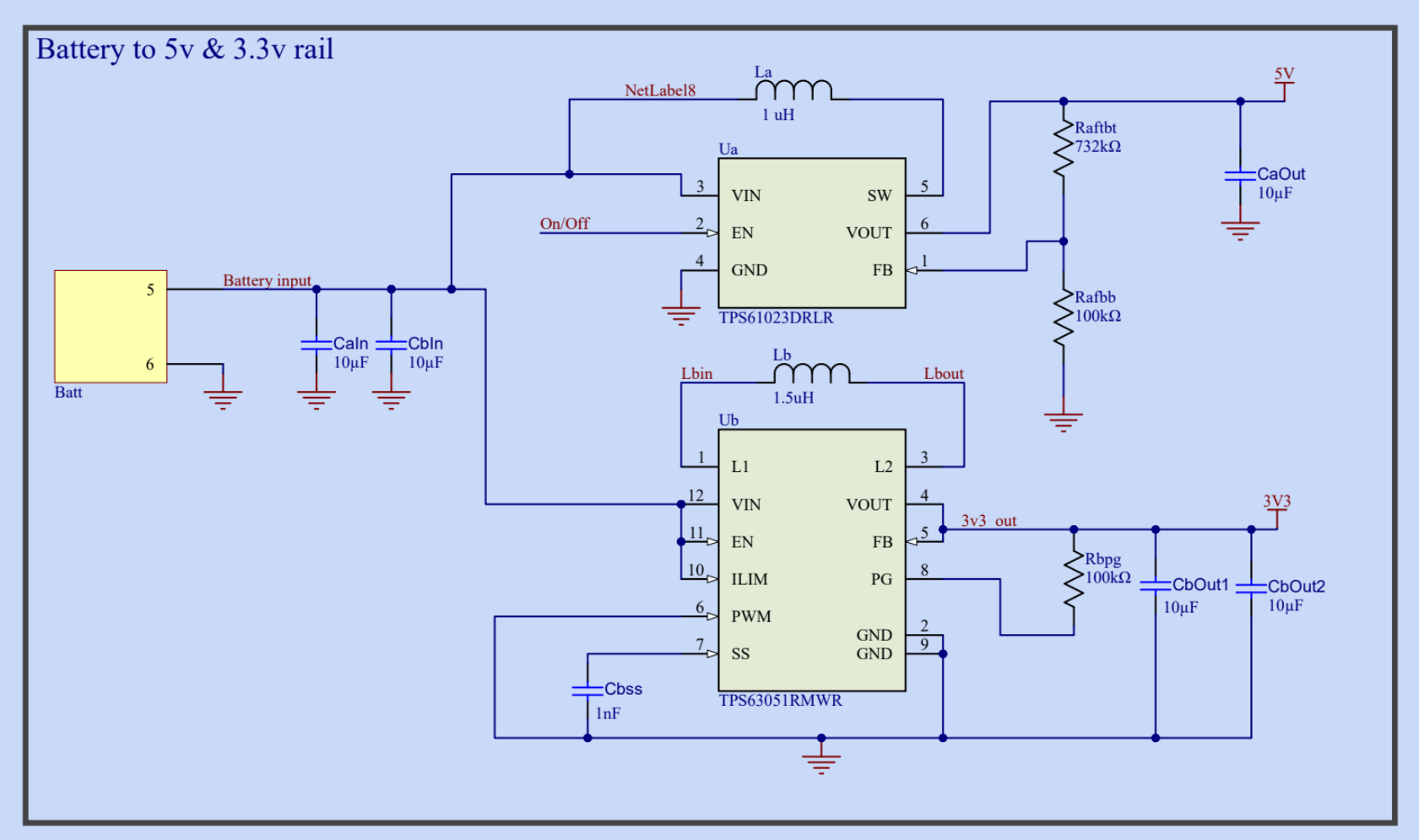

DC to DC power supply

A power supply board was made to test TI DC to DC converters chips for my power requirements. I designed a dev board with two power rails, a 3.3v 200mA high effeciency rail and a higher power 5v 1A for the servo.

- 5v rail

- TPS61023

- Boost converter

- 3.3v rail

This was a lovely development for introduction to DC-DC converters and to distinguish buck from boost converters

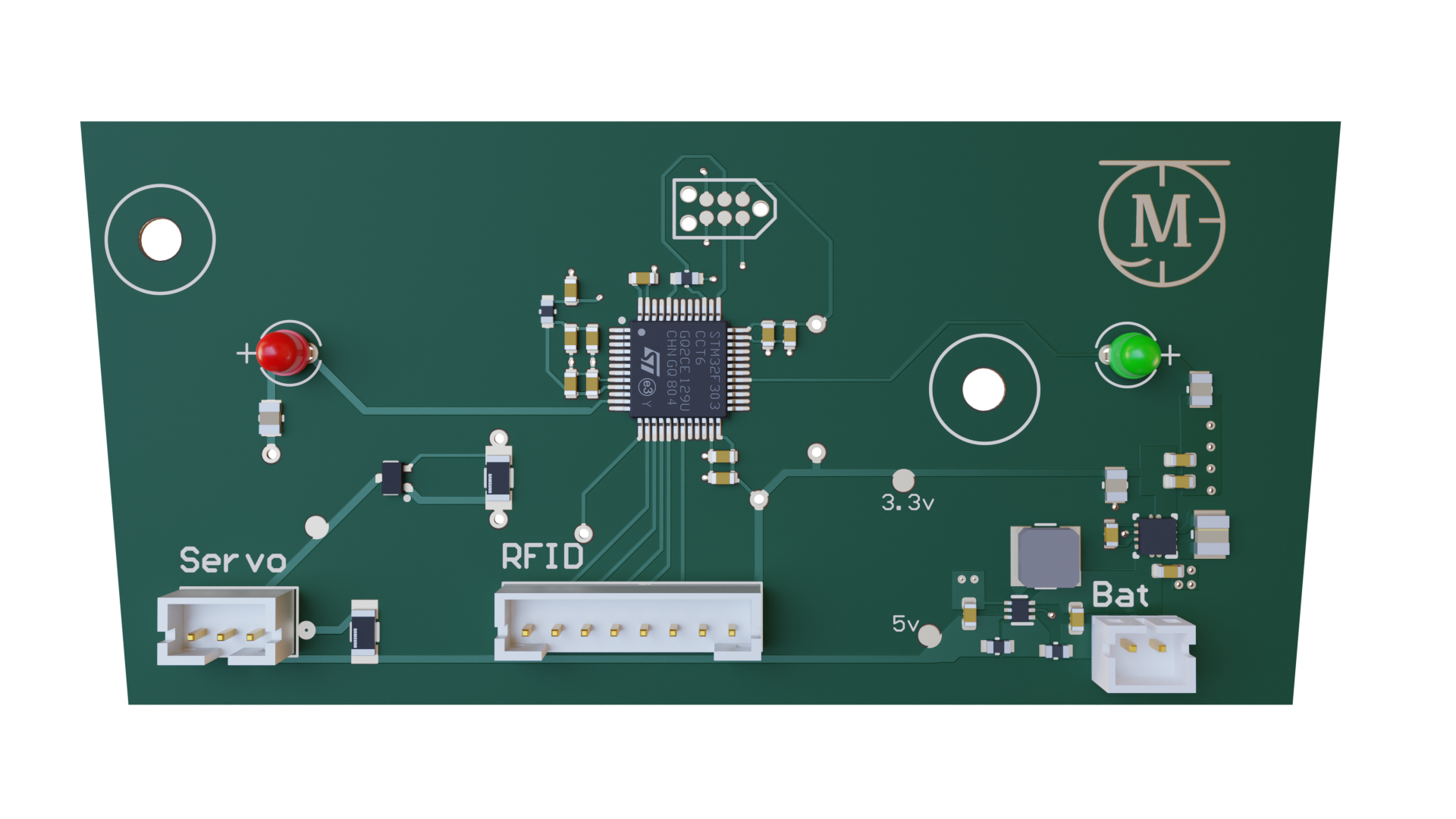

Main PCB

Here I joined the previous power supply work while including the mcu and pereferals.

- STM32F4

- Embedded rust

- DC-DC converter design

- LED design choices

- Logic Level Converter

- Tag SWG connector

- Manufacturing considerations

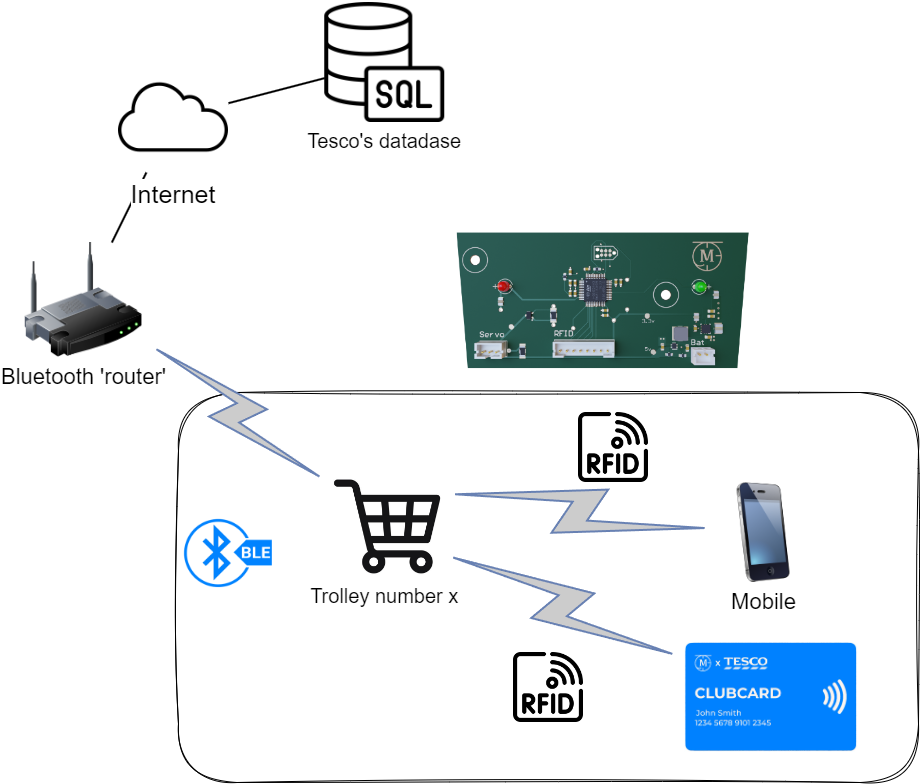

IoT Functionality

- Explain how the IoT system integrates with the hardware.

- Mention key features and benefits, such as remote control and monitoring.

Code & Firmware

Why did you choose rust instead of C?

Good question, I chose rust for the following reasons.

- Safety. It basically meant that it was extremely hard for me to introduce memory safety bugs, even with my lack of embedded experience!

- Rust is a new language compared to C. It let me personally find out what all the fuss is about.

- Rust is backed by a great community. Meaning help was only a few tickets away.

- Most importantly A driver for the RFID reader I was using already existed MFRC522,

- Hierarchical directory structure for embedded rust

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

#![no_std]

#![no_main]

use defmt_rtt as _;

use panic_probe as _;

use stm32f3xx_hal as hal;

use mfrc522::{Mfrc522, Uid};

#[cortex_m_rt::entry]

fn main() -> ! {

// Initialization code for peripherals and configuration

// List of cards with access

let uid_card_pass_1 = [74, 152, 138, 25];

// Peripheral initialization and clock configuration

// SPI configuration for MFRC522

// Main loop for RFID card detection and handling

// Loop for locking and unlocking

loop {

// Main loop content

}

}

// Function for handling RFID card operations

fn handle_card<E, SPI, NSS>(mfrc522: &mut Mfrc522<SPI, NSS>, uid: &Uid, write: bool)

where

SPI: spi::Transfer<u8, Error = E> + spi::Write<u8, Error = E>,

NSS: OutputPin,

{

// RFID card authentication and read/write operations

}

// Panic handler and application termination function

#[defmt::panic_handler]

fn panic() -> ! {

cortex_m::asm::udf()

}

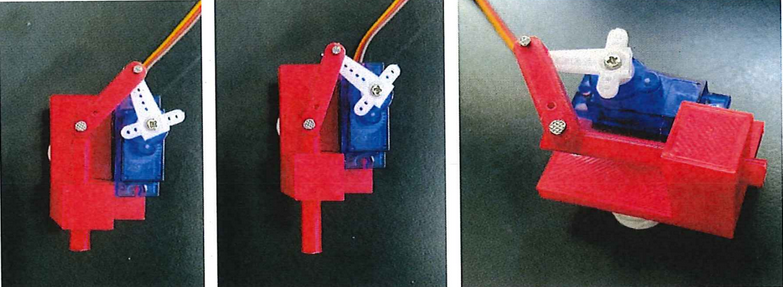

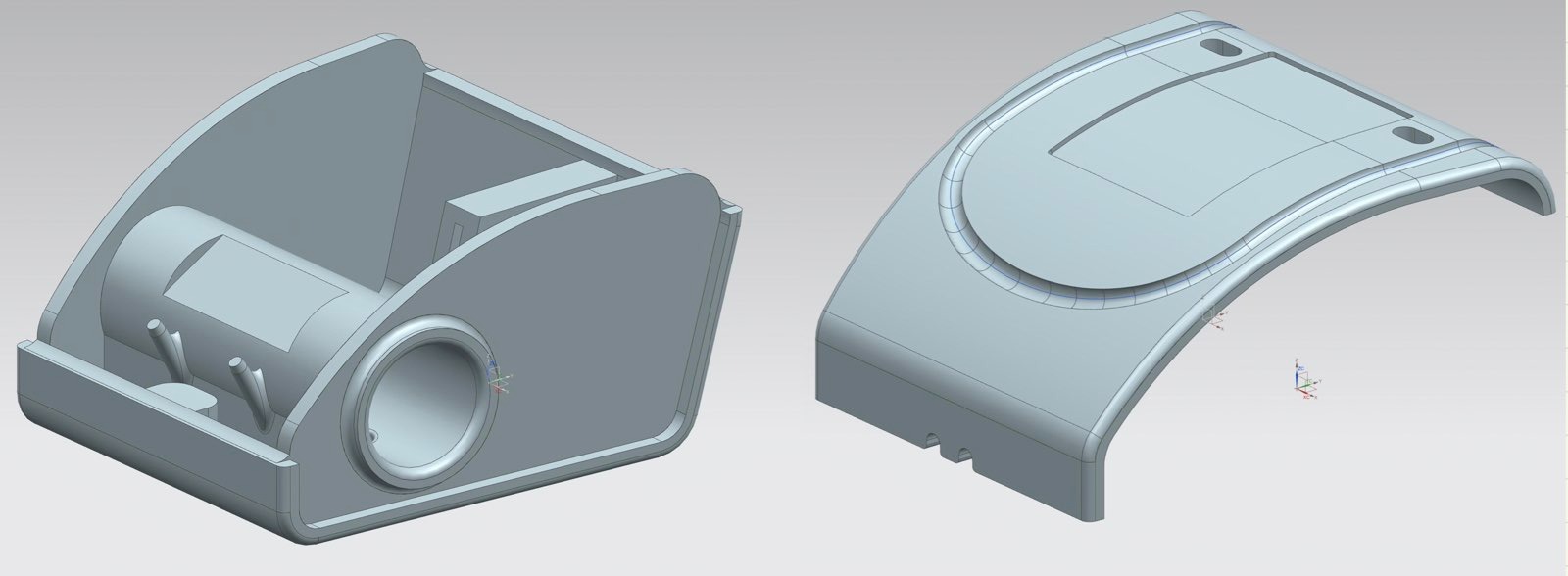

Hardware development Phase 4.

Locking Mechanism

For the trolley to be locked and unlocked, I needed to design a mechanism that could be controlled by a microcontroller instead of a 1£ coin. Initial concept was a Slider crank mechanism where we convert the rotational displace from a servo to a forward displacement to push a pin into the key.

Slider crank mechanism required 3 joins, which would wear down overtime and require lubrication. For a mass produced product, this is not idea.

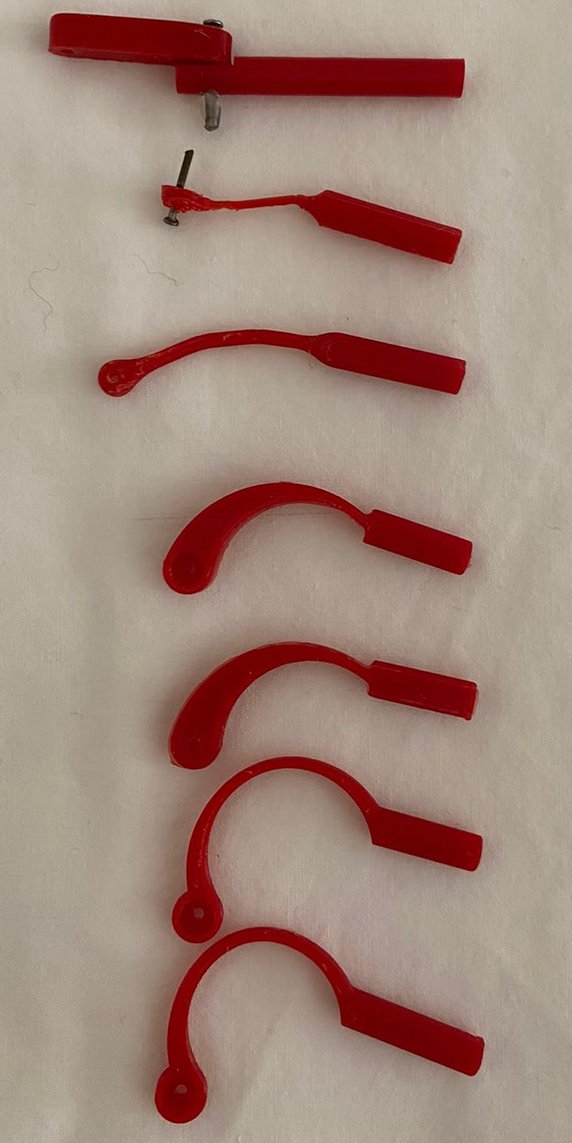

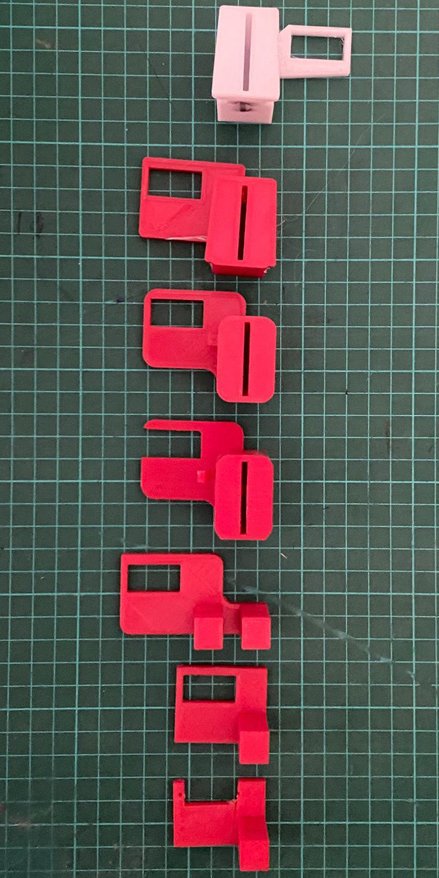

Compliant Mechanism

Exploring compliant mechanisms became the logical next step, especially with the accessibility of a 3D printer, aiming to overcome the setbacks encountered with the slider crank mechanism. The iterative process is vividly captured in the following table:

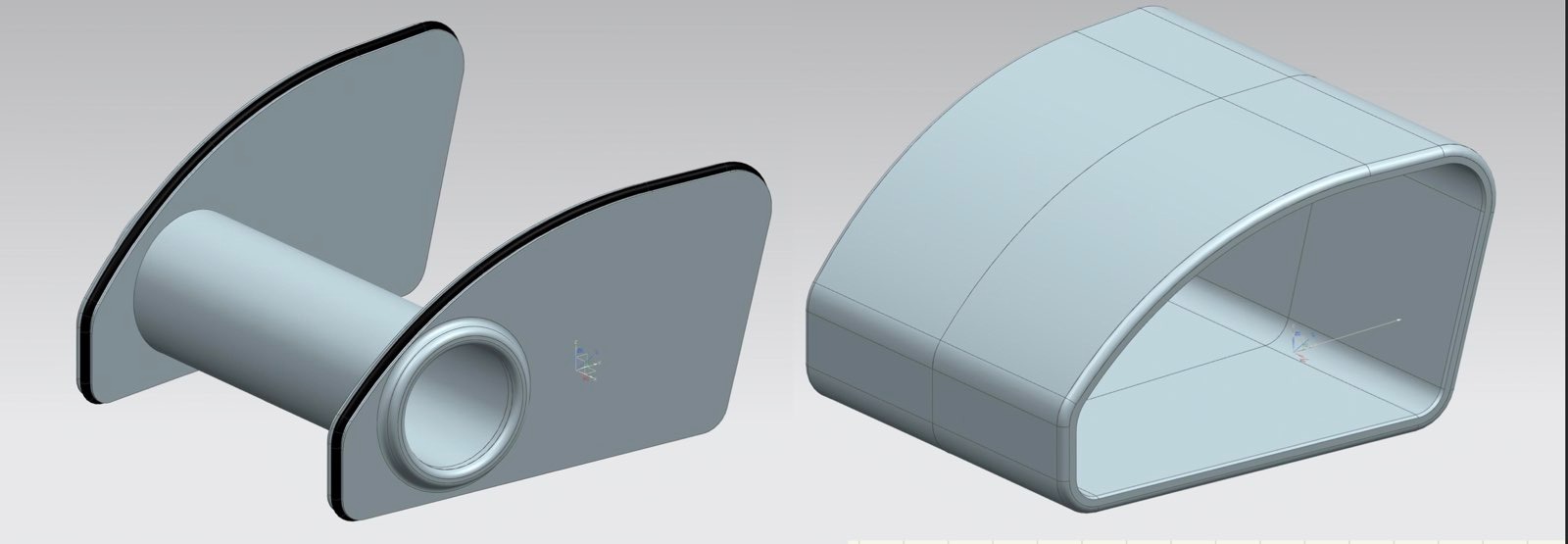

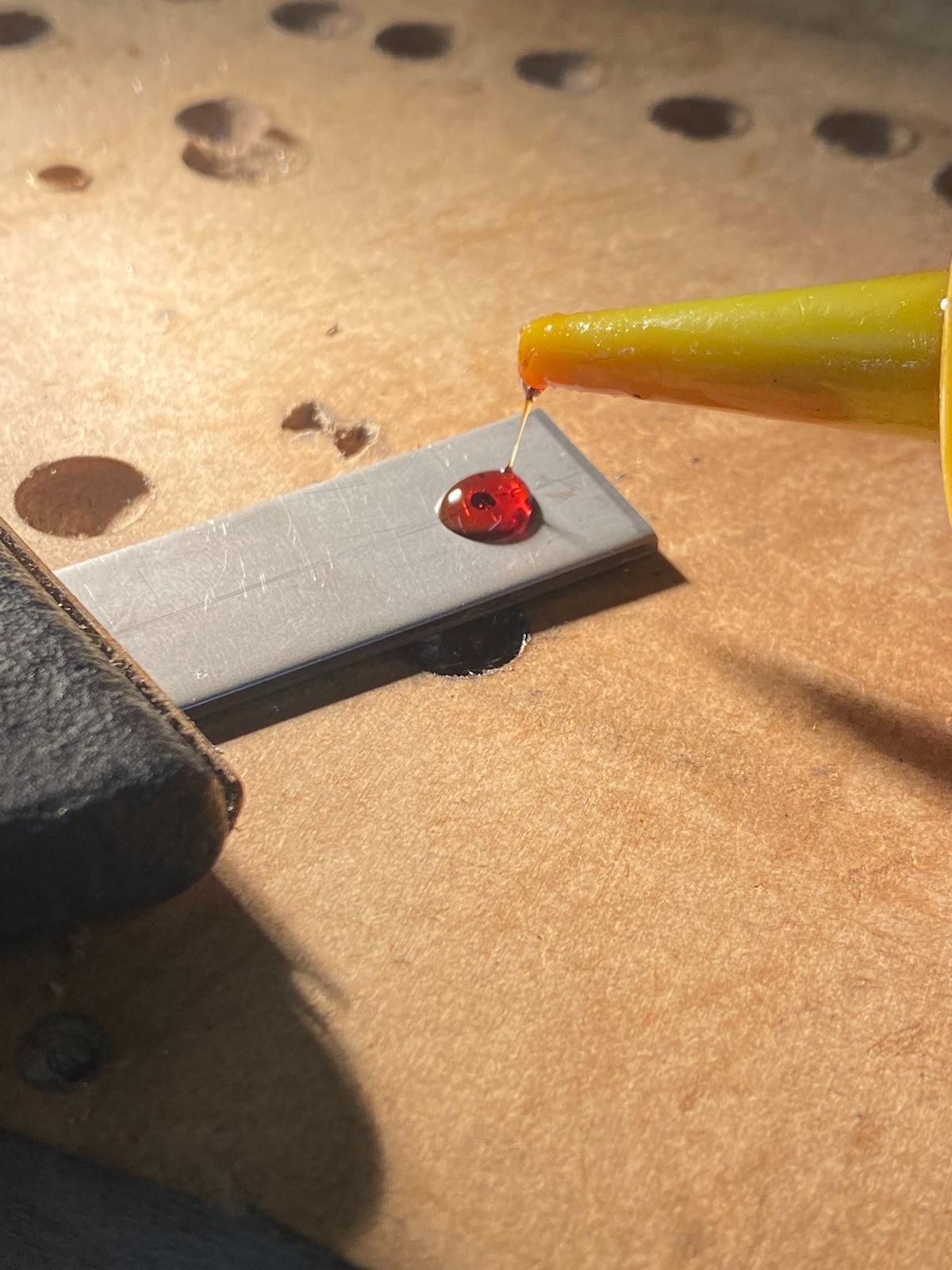

Comparison of O-Ring and Gasket Designs

- The intended solution from ReleaseV1 was to split the case at the seam to hide the split lines.

- Due to all the organic angles and corves this made designing the gasket complicated

Solution: O-ring Design!

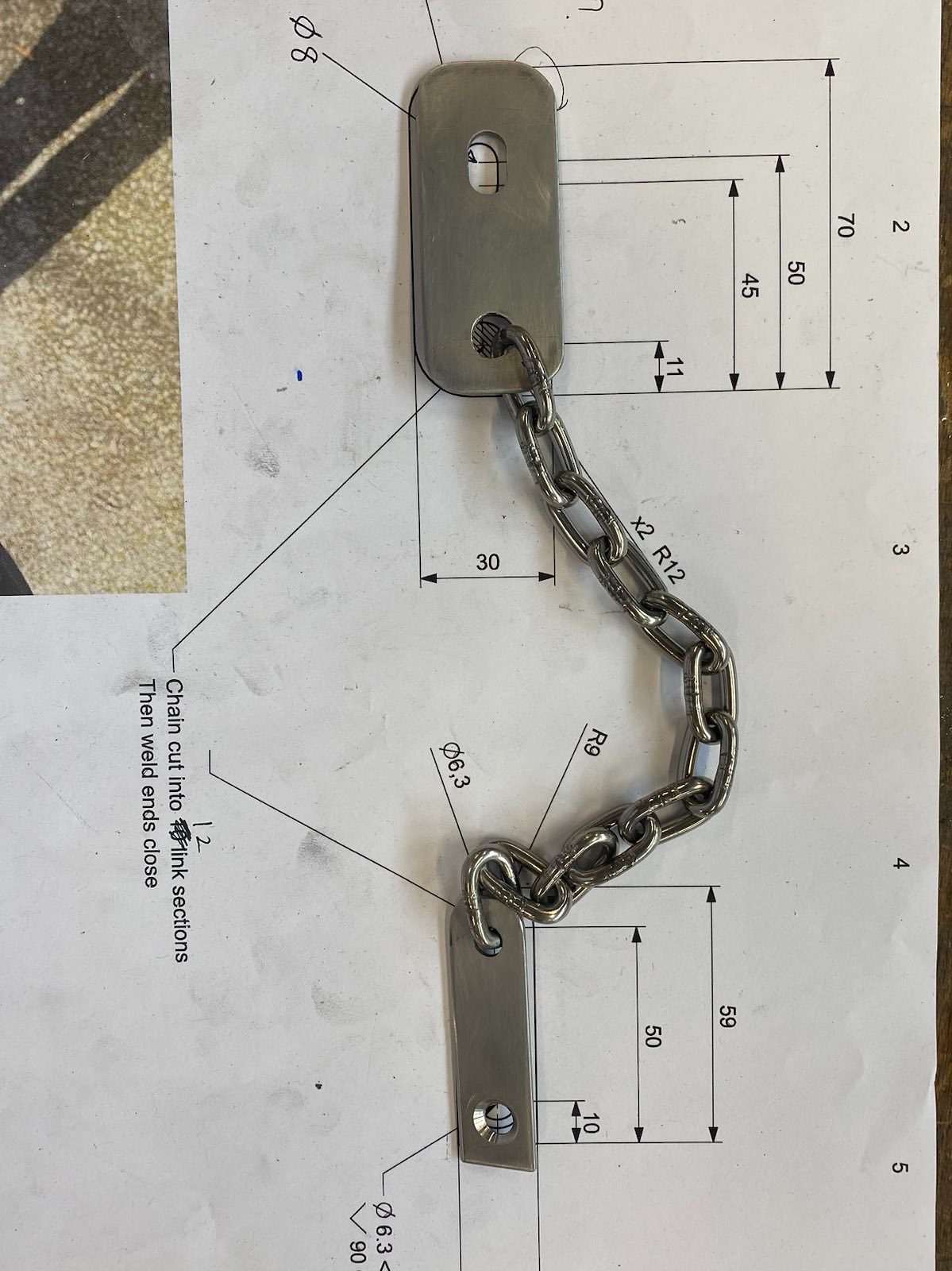

Design of stainless steel key

- Initial thoughts were using aluminium but once I started manufacturing I quickly realised how soft and easy to work with aluminium was… not an ideal material to use for a secure lock.

Conclusion & Contact

- IP34 Rating

- Weeks of battery life

- Fully programmed in Rust

testing